The new products include a series of high-tech and high quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator step-chains, high-speed tooth chains, timing chains, self-lubrication chains, among which have type high speed tooth chain for car branch dynamic box and aerial chains fill in the blanks of chain in China.

Overview

Quick Details

-

Applicable Industries:

-

Manufacturing Plant

-

Pole:

-

single stage two stage three stage four stage

-

Ratio:

-

16

-

Housing Material:

-

Cast Iron

-

Material:

-

20CrMoTi

-

Working temperature:

-

-40~45℃

-

Type:

-

ZLYJ 173/200/225/250/280/315/375 twin screw Extruder Gearbox for

-

Process:

Under the guidance of managerial sense of “Serving agriculture, scoring a success through quality of products and honesty in business”, our products have been trusted by clients and have gained a larger share of market.

-

Carburizing, Nitriding , Grinding

-

Efficiency:

-

92%~96%

-

Mounting Position:

-

Horizontal,Vertical,Flange

-

Color:

-

Blue,Green,Gray,Red

Packaging & Delivery

-

Lead Time

:

-

| Quantity(Bags) |

1 – 20 |

>20 |

| Est. Time(days) |

15 |

To be negotiated |

Online Customization

Product Description

PROFESSIONAL MANUFACTURE

—— SINCE 1995

ZLYJ Extruder GearBox

Ever-Power Machinery —— Tianqi Brand industrial gearbox manufacturers

ZLYJ 133/173/200/225/250/280/315/375

twin screw Extruder Gearbox for plastic extrusion machine

Main Series Product: R series helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer,ZLYJ Series twin screw extruder gearbox for extruder machine, etc. Meanwhile, map sample processing business can be undertaken.

Widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

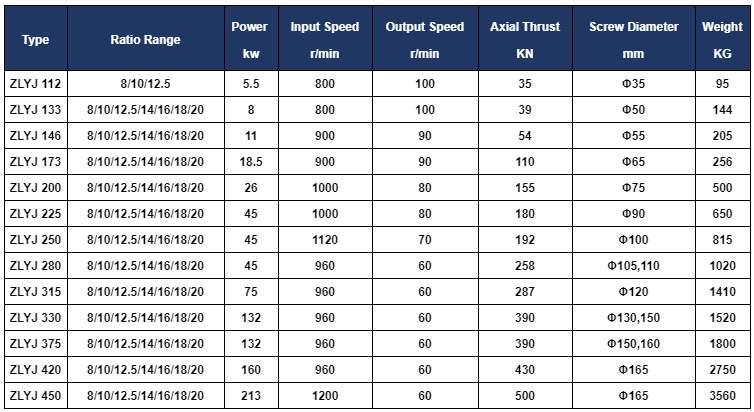

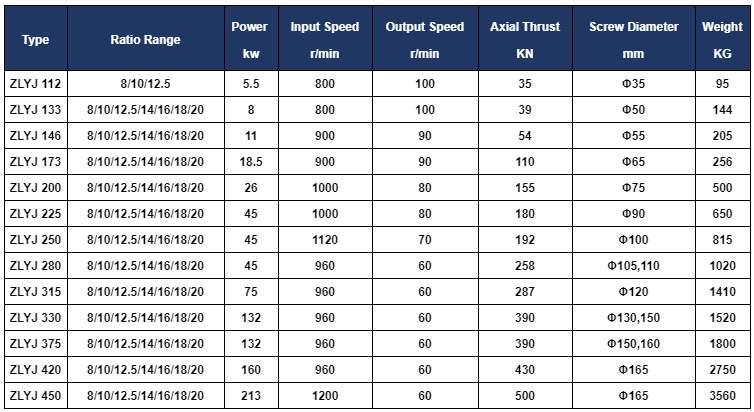

Specification

ZLYJ 133/173/200/225/250/280/315/375 twin screw Extruder Gearbox for plastic extrusion machine:

Feature:

-

Realized parallel shaft,right-angle shaft modes and horizontal,vertical mounting modes. Using less component parts.

-

Applying advanced grinding process which improved the stability and the efficiency of transmit power with lower noise.H B Bevel helical reduction gearbox 50:1 for bucket elevators.

-

Input mode: motor connected flange, shaft input.

-

Output mode:solid shaft with flat key,hollow shaft with flat key,hollow shaft with shrink disk,hollow shaft with spline connection, solid shaft with spline connection, solid shaft with flange.

-

Mounting mode:vertical, horizontal, swing base-mounted, torque-arm-mounted.

-

Ratio range:8~20.

| TYPE |

ZLYJ133 |

ZLYJ146 |

ZLYJ173 |

ZLYJ200 |

ZLYJ225 |

ZLYJ280 |

ZLYJ315 |

ZLYJ330 |

ZLYJ420 |

| n |

8 |

8 |

8 |

12 |

12 |

12 |

12 |

12 |

12 |

| d3 |

M12 |

M12 |

M16 |

M16 |

M20 |

M20 |

M24 |

M24 |

M24 |

| center distance |

205 |

230 |

260 |

300 |

370 |

400 |

405 |

450 |

580 |

Model selection ZLYJ 133/173/200/225/250/280/315/375 twin screw Extruder Gearbox:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo moPTO shaft connectors on tractors are not standardized which can lead to complications when connecting the PTO shaft. For example, some older tractor models have the connection flange closer to the tractor itself making it difficult to connect and lead to a potential safety hazard.dels on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide. ZLYJ 133/173/200/225/250/280/315/375 twin screw Extruder Gearbox for plastic extrusion machine.

Company Information

Established in 1995 , HangZhou Ever-Power Machinery is a professional manufacturer and exporter that is concerned with the design, development and production of Gearbox Speed Reducer. We are located in HangZhou of ZheJiang Province, with convenient transportation access. With our own brand “EPG”, all of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our company possesses complete machining center, lathe, gear shaping machine, gear milling machine, gear grinding machine and assembling lines. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Besides, In 2005,we attained ISO9001 certification. As a result of our high quality products and outstanding customer service, we have gained a global sales network reaching South America, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other countries and regions.

Chinese Gear Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construA seal-journal surface that features an inverted shot-peened texture, with raised (rather than indented) spherical lobes and corresponding valleys in between, better supports hydrodynamic lubrication. EPT developed a process that compresses seal journals between burnishing dies that have been peened to create random spherical depressions. This leaves an “orange peel” texture on the journal surface, typically with a 20 to 40-m in. surface roughness.ction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products. ZLYJ 133/173/200/225/250/280/315/375 twin screw Extruder Gearbox for plastic extrusion machine.

Packaging & Shipping

ZLYJ 133/173/200/225/250/280/315/375 twin screw Extruder Gearbox for plastic extrusion machine

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!